CHALLENGE 1

Joint Inspection and FFS

-

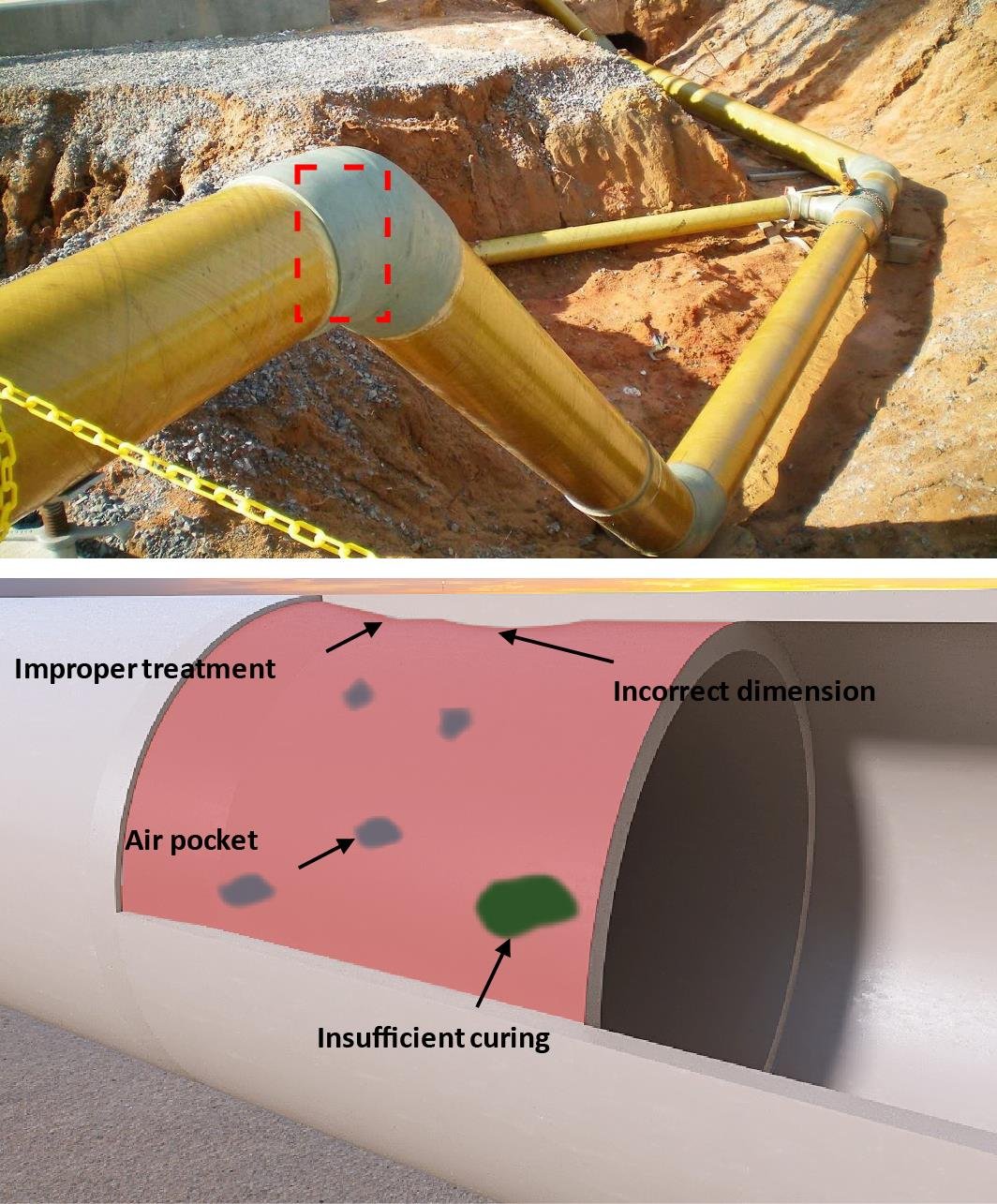

RTR joints are critical yet often have low confidence levels due to defects such as improper surface preparation, insufficient curing, dry joints and incorrect tapering geometry. Current inspections (visual and hydrotest) may not detect defects that compromise long-term integrity.

-

Develop a method to validate joint fitness-for-service at installation by:

• Identifying defect types and their criticality.

• Surveying and enhancing inspection techniques.

• Correlating defect observation to fitness-for-service.

-

• Materials: GRE pipes with thermoset adhesive joints (e.g., FuturePipes).

• Working conditions: 180°F/82.2°C, water/oil/gas, 8”–36”/203.2–914.4mm OD.

• Inspection before burial, with joints fully accessible externally.

• System must be easy to handle, low-cost, and operable by technicians.

CHALLENGE 2

Inspection Under Composite Repair

-

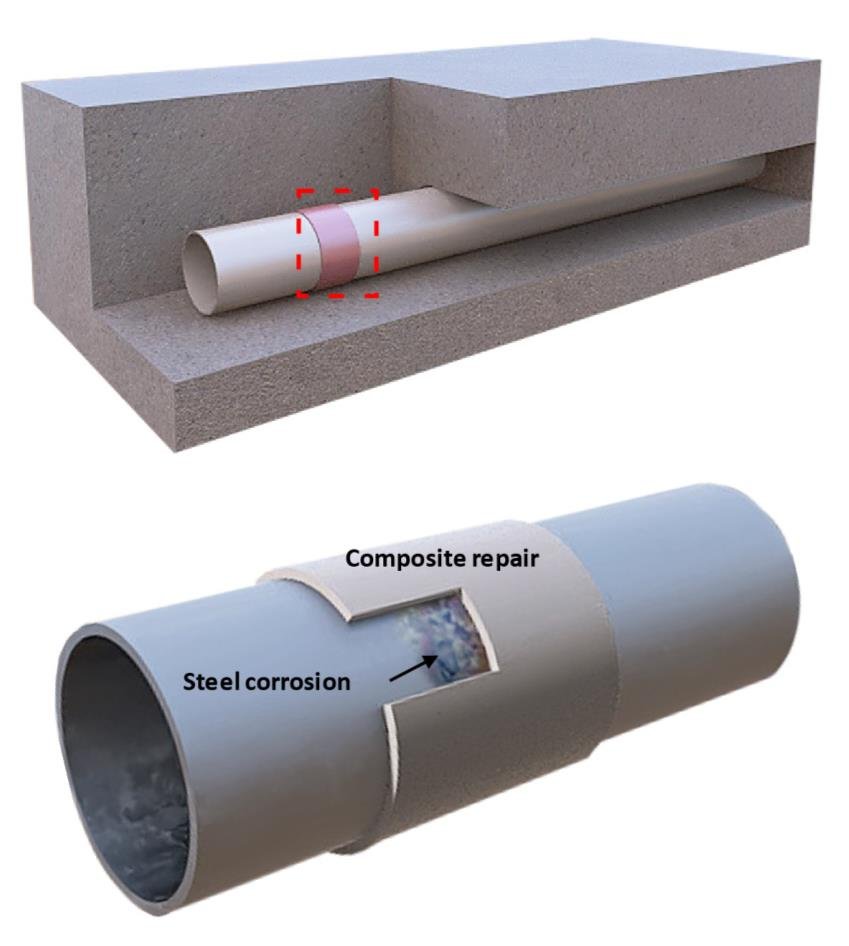

• Composite repairs are widely used for steel pipe rehabilitation, but inspecting for internal/external metal loss and damage at the composite-metal interface remains challenging.

• Existing techniques (e.g., multi-skip and pulse eddy) require continuous physical pipe access (remote-control post-installation).

-

Develop a tool to:

• Quantify corrosion rate in steel pipes under composite repairs without physical access after installation.

• Enable full 2D corrosion mapping.

-

• Pipe material: Carbon steel.

• Repair material: GFRP/CFRP (epoxy or PU-based).

• Operating conditions: 180°F/82.2°C, water/oil/gas, buried 1–2m depth.

• Cost: Low.

CHALLENGE 3

Inspection & Pigging (ILI) for (buried) composite pipes

-

• No proven Inline Inspection (ILI) tools exist for Non-Metallic (NM) pipes, particularly multi-layered RTP structures, making it difficult to gather layer-specific data.

• Current strategies (“fit and forget” or hydrotesting) are effective but lack validation through ILI tools.

• An Inline Inspection Strategy (IIS) is required to locate and validate damaged “hot spots” along pipelines.

-

Develop an IIS for RTR and RTP pipes to:

• Detect cracks, delamination, aging, and permeability issues.

• Determine if inspection should be internal (e.g., PIG tools) or external.

-

• Operating conditions: 180°F/82.2°C (water), 221°F/105°C (hydrocarbon).

• Flow rates: 1–25 m/s (varied by fluid type).

• Pipe size: RTR (6”–30”/152.4–762mm OD) and RTP (thermoplastics, carbon steel liners).

• Inspection scale: >10 km, no production interruption.

• No existing insertion infrastructure; feasibility to be explored.

CHALLENGE 4

Remote Monitoring of Critical Areas

-

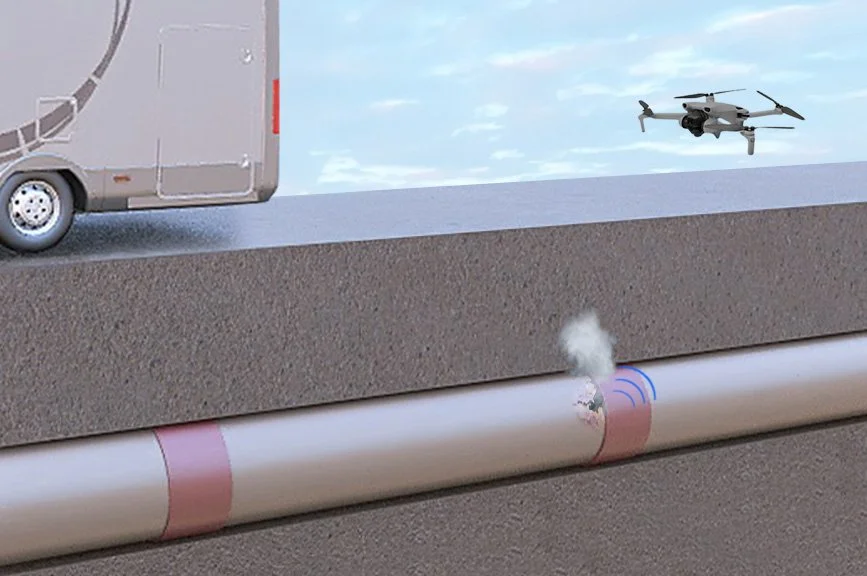

Critical areas, such as joints, elbows, and repairs, often experience most failure events. Monitoring these areas requires permanent, remotely interrogable inspection tools.

-

Develop remote monitoring techniques for critical areas, enabling fitness-for-service (FFS) assessment.

-

• Identify and integrate inspection methods for remote monitoring.

• Enable remote inspection through air, water, or soil.

• Develop structural health monitoring (SHM) schemes for FFS evaluation.

-

• Pipe material: GRE, RTP.

• Service conditions: Up to 203°F/95°C, water/oil/gas condensate.

• Pipe size: 6–24”, buried 1–2m.

• Technology must ensure sufficient accuracy for FFS calculations.